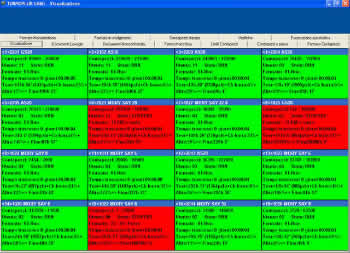

| In order to improve the productive process control the company has been equipped with the following programs that connects you to the machines server and allows you to realize statistics and diagrams for various units:

|

|

|

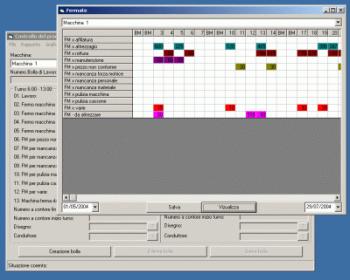

Machines status - It manages the times of work, various state times of the machines. Diagrams can be obtained in order to confront various units. The same program allows us to visualize the end of production for every machine and type of product. The machine chief can themselves be characterized also. |

|

Quality - This software module allows us to manage the various happened not-conformities. Statistics for every type of not-conformity, time of selection, amounts and times of selection can themselves be carried out. |

|

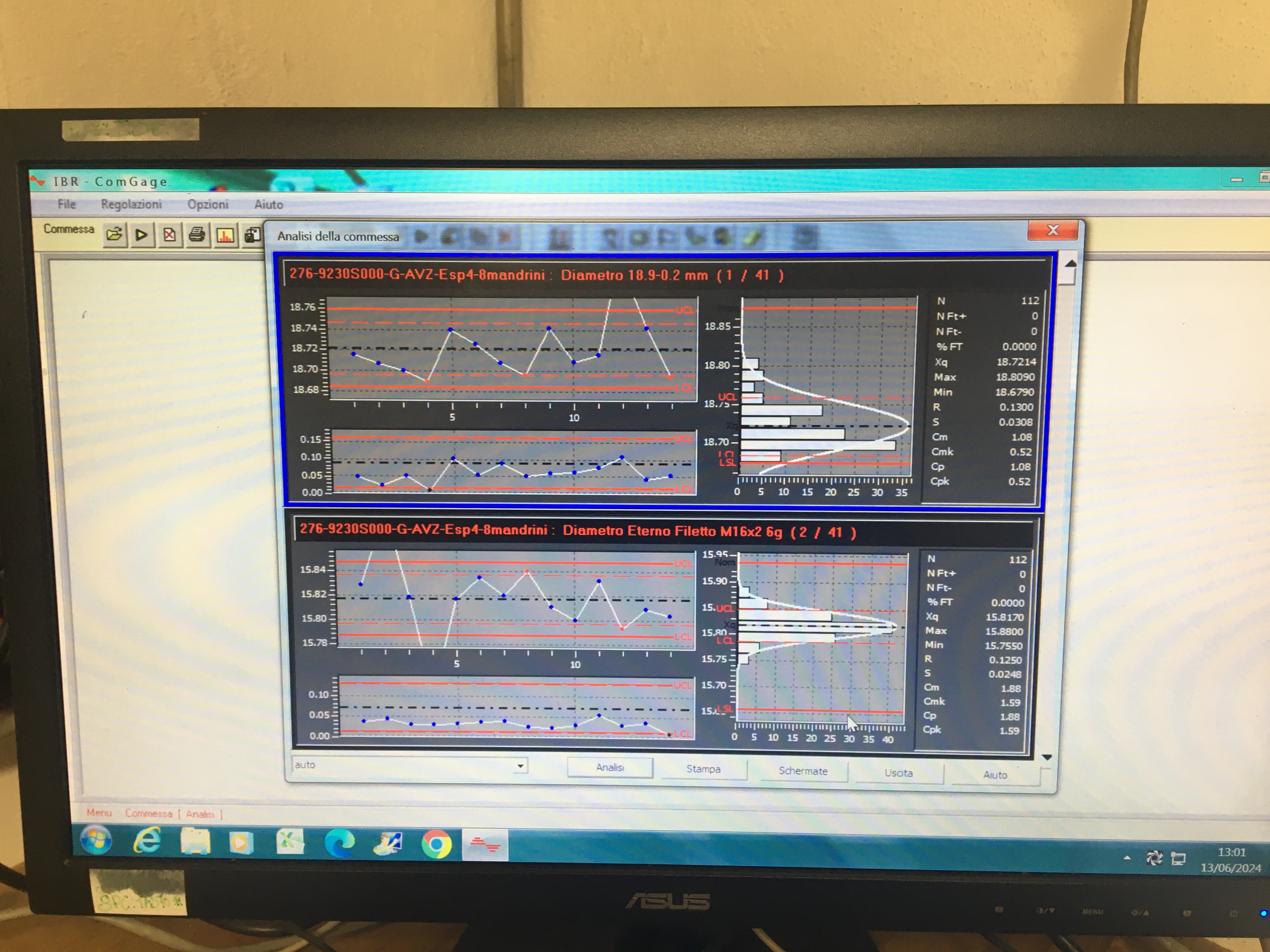

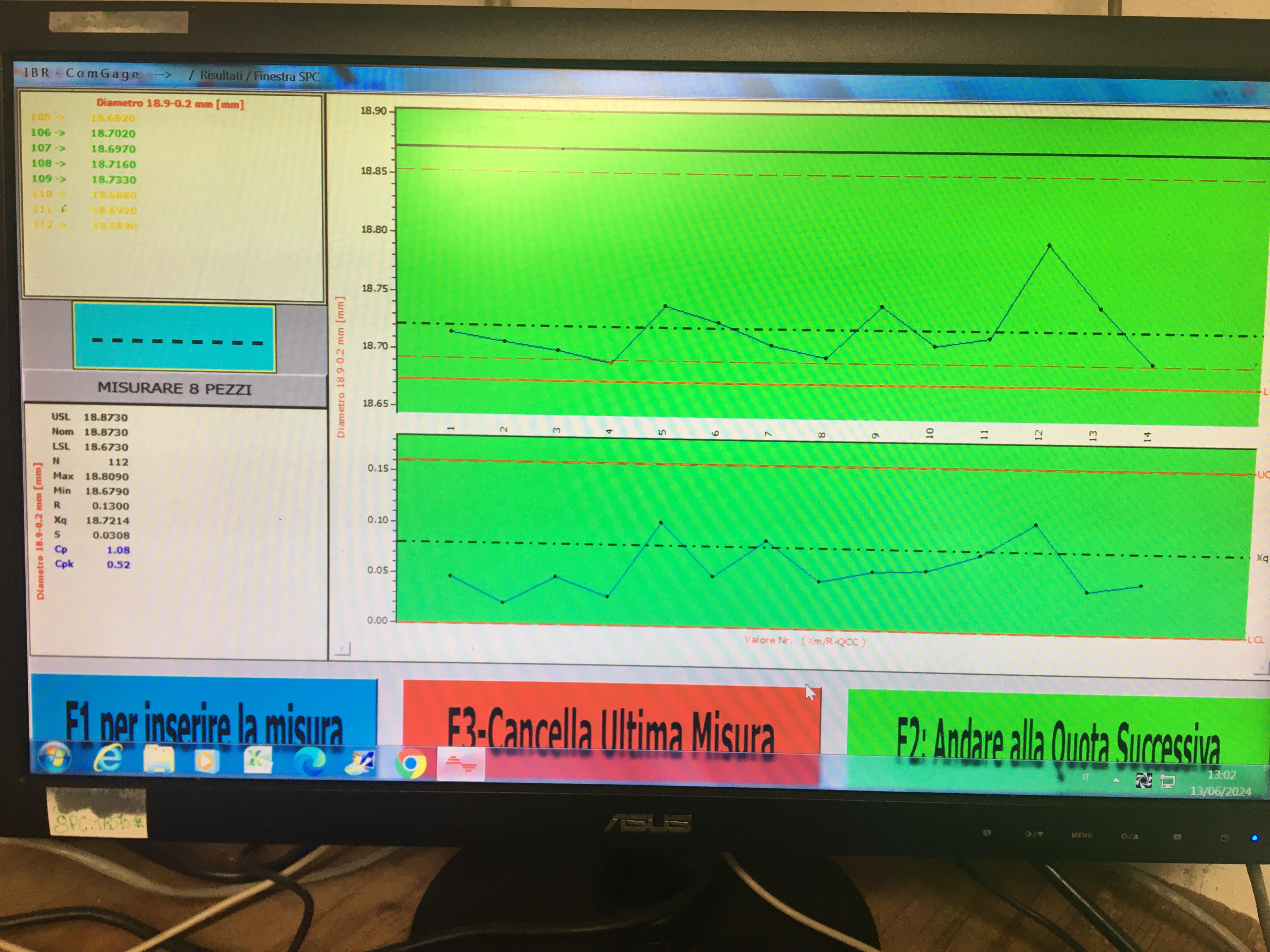

Calculation CPK |

|

|

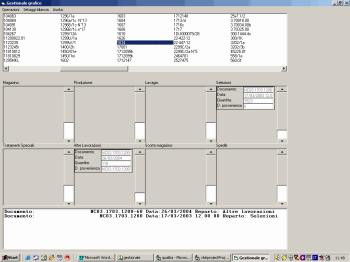

Managerial - a program module for internal use only concurs to control the transfers of the product between various units of the company. In every moment the distance of a pieces lottery can be seen (given and number of the transfer document). |

|

|

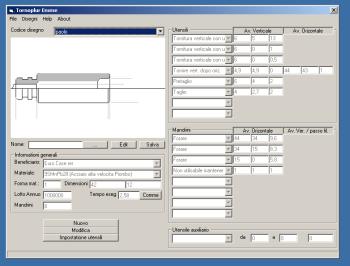

Designs - an important module used to create the estimates, and to calculate the time of execution of a piece. This module concurs to characterize all necessary requirement for the planning of the production process and allows to calculate advances, number turns for tools and to optimize the tools in the machine, leaving from the type of machine that will come used. The same module allows to find the lottery of production for a better relationship placing/production. |

|

: Balances - the module for the exits from the unit selections departament, can be used control weight and quantity in a very simple way still connected to Informatic System. |

|

|

The machine server receives the main signals from the machines (counters, job ends, breaches: lack oil, lack pressure up to a maximum of 16 marks), it prints the transfer documents for various units, and contains the necesary modules for the set up of the machine (like maintenances, aim production, and monitoring). |